COMPOSITE WOOD DECKING STRUCTURE MATERIAL

Options for the structure and framework materials for your Best Deck composite wood products

Underestimating the importance of the structure or framework is a costly mistake that Best Deck frequently encounters and addresses. In the installation of composite wood products, ensuring a solid, rigid construction using the highest quality materials is paramount. This approach guarantees the longevity of the composite wood products, helping them to exceed their expected lifespan and outlast their warranties for the specific application.

The cost of making poor decisions when selecting the best structures

The financial implications of not securing the best structure or framework options become apparent over time. At Best Deck, our experience has taught us to always over-engineer the framework rather than merely meeting standard installation requirements. Over-engineering does not necessarily entail significant additional costs — in many cases, there are no extra costs at all. It involves paying attention to detail and ensuring the structure or framework is rigid in every aspect. These efforts will ultimately make a significant difference to the long-term durability and performance of your composite wood products.

Building a solid foundation

The framework or structure serves as the foundation for any planking system installed upon it. Similar to constructing a house, if you build on a poor foundation, the building will eventually fail. Likewise, if you install composite wood planking on a subpar or incorrectly installed framework, the product will ultimately fail. Ensuring a strong and properly installed foundation is essential to the success and longevity of your composite wood planking system.

Our combination of knowledge and experience means Best Deck are composite wood experts

At Best Deck, we have learned through experience and know the best structure or framework options for any given application. Coupled with our expertise in the commercial application of all our Best Deck composite wood products, we are specialists in what we do.

Best Deck turnkey product and installation solutions

When Best Deck quotes on turnkey supply-and-install options, you are assured that we have provided the very best of everything. If Best Deck is handling your project, we guarantee all aspects, including the structure or framework, ensuring it is built correctly to exceed its intended lifespan.

Additionally, when Best Deck is your contractor of choice, consider the following:

1. Over-Engineered framework Our installation ensures that the structure or framework is over-engineered to last beyond its designed timeframe.

2. Proper planking installation We adhere strictly to the correct installation methods, avoiding back-to-back composite wood planking. Instead, we use what Best Deck refers to as a breaker board, which not only enhances aesthetic appeal but can also be done in a contrasting colour for a beautiful finish. Breaker boards ensure no back-to-back joins in a Best Deck installation.

Expertise and professionalism sets us apart from the rest

Our expert team has many years’ experience in the composite wood industry

At Best Deck, we strive for the very best end result for every project. A lot of companies fall short here. This is where, when it comes to comparing prices, it is critical that one is comparing a specialist in the industry’s price to another specialist in the industry’s price. Is the structure or framework material of the same specifications (size, thickness, and even type)?

Daily, we deal with enquiries where the potential client is comparing a timber deck structure to a galvanised steel structure. Although the galvanised steel price often is not much different to natural timber, this isn’t a wise approach to an apples-for-apples comparison.

Perfection is the ultimate result we always strive to achieve

The finishing details must receive the attention they deserve, as this are what everyone notices. At Best Deck, we fully understand this important concept. We know that even if we build a stunning 500 square metre deck, just one or two loose fascias can spoil the entire appearance. Until those are fixed, our client won’t appreciate the beautiful deck — they’ll only see the flaws. We get that.

When Best Deck supplies and installs your composite wood project, this includes our structure or framework and our full-time after-sales service team. We have full confidence that any maintenance issue under the Best Deck guarantee will be minor and easily resolved.

As in every industry, things can occasionally go wrong. At Best Deck, we prioritise efficiently addressing customer service-related issues. Your satisfaction is our priority.

At Best Deck, we understand you, our esteemed client

The reason all of this information is relevant to our composite wood material structure page, is that achieving the desired end result requires starting with the correct foundation — the structure or framework.

Best Deck supplies all our products to anyone who wishes to purchase them. We have contractors and clients both nationally in South Africa, in southern Africa as well as further afield internationally. Our clients purchase the structure materials they need for their specific projects and also support Best Deck by buying the composite wood profiles they require.

At Best Deck, we go out of our way to ensure our clients always receive the best service. This includes providing the correct information to ensure you purchase the appropriate composite wood materials for your needs. We ask that when enquiring or ordering a product, you provide accurate information relating to your request. This is crucial for both parties to be on the same page.

STRUCTURE MATERIAL OPTIONS

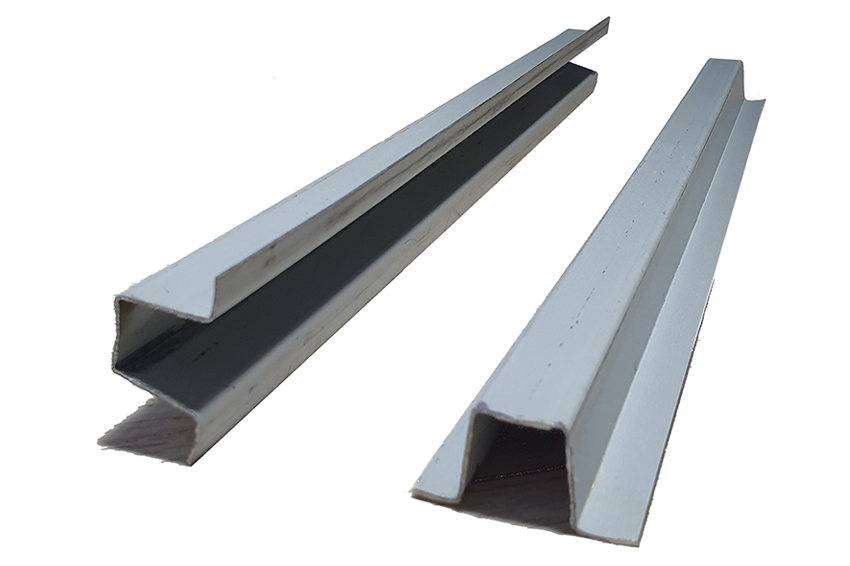

Lightweight Galvanised Steel – C Channel – 1.2mm thick – 1.2mm wall

Galvanised Steel Structures and Framework – For Inland Projects

On inland projects, Best Deck does not use timber in a normal application as the supporting material (there are exceptions). In regions where the air is dry, with very hot and then very cold conditions, rain and moisture (like the Highveld, Gauteng), timber does not generally work well. Trying to maintain timber structures or frameworks in these conditions becomes overwhelming and impractical. In some cases, you have limited access to what you can see and maintain. In these cases, a galvanised steel frame makes much more sense.

Timber is a natural product. So, it has a limited life span. Without constant nourishment from wood preservatives, the lifespan of a timber product decreases very quickly and dramatically. It only makes sense to use a durable material. The best material we currently have available in our industry is galvanised steel. So, all of Best Deck’s inland projects are done only using galvanised steel or our solid plastic or composite wood profiles.

This 1.2mm wall thick x 65mm x 35mm x 15mm(as it a C Channel) x 6000m Long Light galvanised steel is suitable for any and most residential projects and can also be used in commercial projects, Best Deck use it all the time

Galvanised Light weight C channel is a standard stock item.

Top Hat Light Weight Galvanized Steel – Wall Cladding

This steel is specifically for the Wall Cladding and Fluted Wall panelling

Solid Composite Wood Joists

This is an amazing profile that lasts for a very long time. It is also 100% maintenance-free, and is rot- and termite-resistant. While there are various other applications for this profile, this is possibly the best profile available for the structure or framework for your composite wood installation and application. For this reason, it costs more than all the other structure options.

This solid composite wood profile can be machined like timber. It can be reduced in size or thinned out to accommodate installations where the space is limited. For example, if a door needs to open over the deck, the plank thickness can be reduced so that it fits comfortably between the existing floor and the bottom of the door.

This profile can have a small void between the ground and this joist, unlike the recycled plastic joist. It is very strong when it is supported at 350mm spacing and gives an even better result than galvanised steel.

If you are going to apply this installation application, please ensure you use an expert to avoid very costly mistakes.

Solid Recycled Plastic Joist

Being 100% maintenance-free and resistant to rot and termites, this is the perfect profile to use, provided it is on an installation application that is on something level and solid (like a level concrete or tiled surface).

These recycled plastic battens /joists/ spacer profiles work well when there is no void (gap) between the joist and the solid surface. They like to sit flush onto a solid foundation and are ideal for conditions where one does not require a raised structure. All composite profiles require support or a spacer and cannot be fitted directly to a surface.

This installation application requires an expert.

CCA Pressure treated timber

Timber Structures and Framework – For Coastal Projects

For structures and frameworks that are erected or installed at the coast, close to the sea, or where there is a high salt content in the air, timber is the way to go. But, the correct timber and the correct timber type are essential.

In our industry, CCA treated pine is usually the timber of choice. BUT, CCA pine and pressure-treated CCA pine are very different. Pressure-treated timber undergoes different treatments and is treated to different H Factors. H1 is the lowest and H5 is the highest. H4 or H5 pressure-treatment timber is optimal. In addition to this, a Waksol / carbolineum or bitumen treatment must and should be done to the timber too.

On a timber structure or framework, it is always better to go a bit chunkier on the material. Going thicker on the timber sections often does not add a lot to the bottom line, but will make a big difference to the longevity of the timber structure. A heavier, chunkier piece of timber means a longer lifespan.

50mm x 25mm Rectangle Mild Steel Tube

Available in 6 meter lengths

Mild Steel Tubing – Generally available in 24 hours on standard off the shelf items

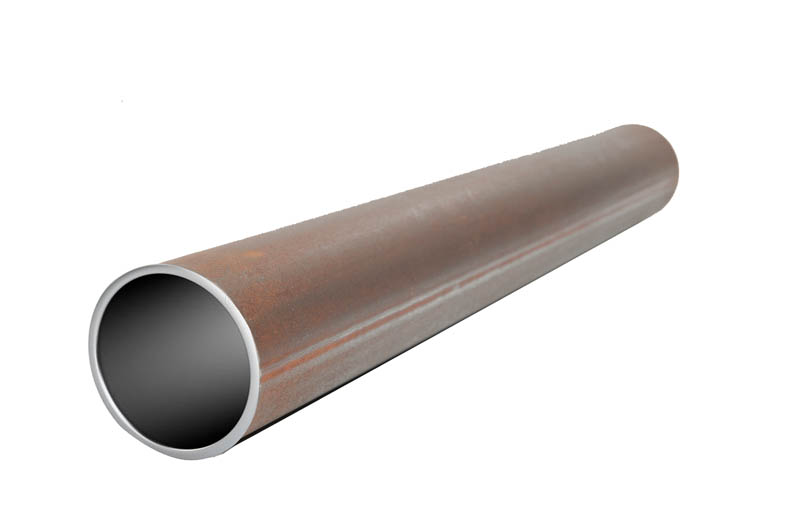

50mm Round Mild Steel Tube

Available in 6 meter lengths

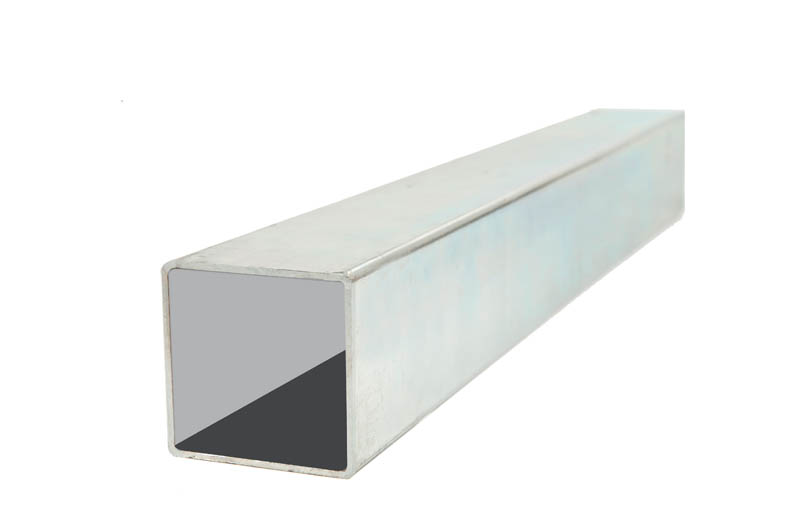

75mm Square Galvanised Steel Tube

Available in 6 meter lengths

Galvanised Tubing – 4 to 7 working days subject to quantity

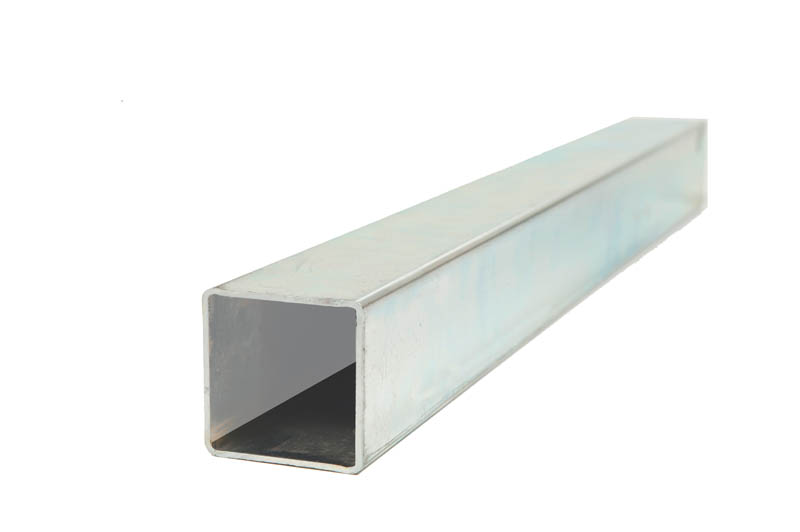

50mm Square Galvanised Steel Tube

Available in 6 meter lengths

Galvanised Tubing – 4 to 7 working days subject to quantity

25mm Square Galvanised Steel Tube

Available in 6 meter lengths

Galvanised Tubing – 4 to 7 working days subject to quantity

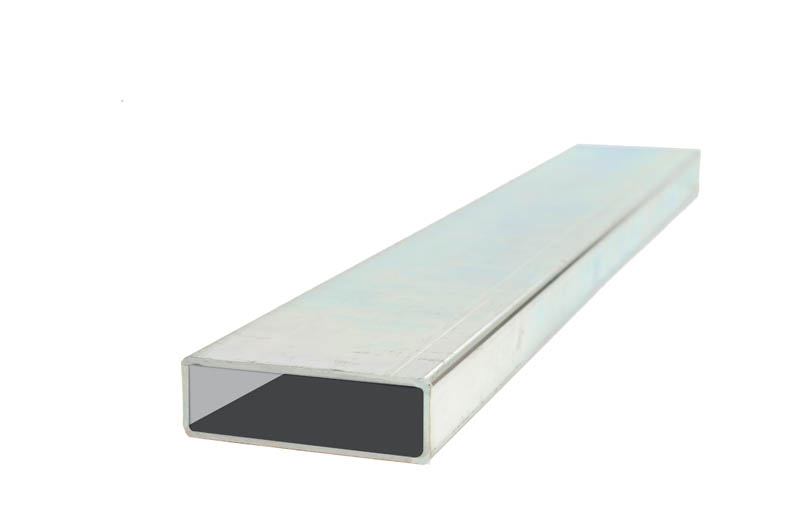

75mm x 25mm Rectangle Galvanised Steel Tube

Available in 6 meter lengths

Galvanised Tubing – 4 to 7 working days subject to quantity

50mm x 25mm Rectangle Galvanised Steel Tube

Available in 6 meter lengths

Galvanised Tubing – 4 to 7 working days subject to quantity

Structure Material Gallery